Production process

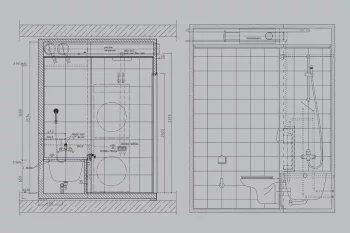

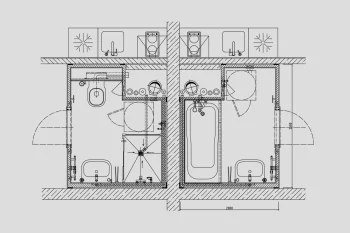

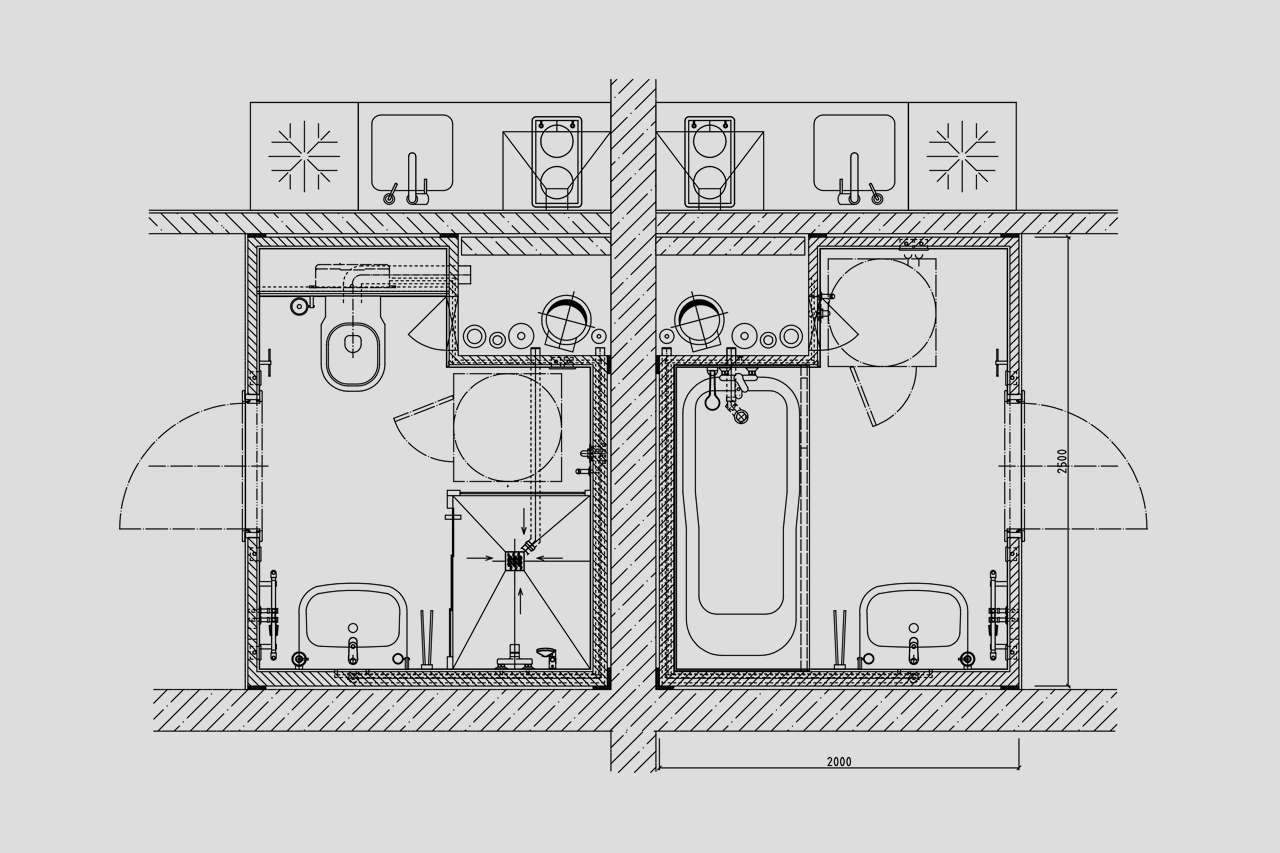

Prefabricated bathrooms are, based on individual requirements and ideas of every client, designed and subsequently manufactured and assembled in our factory.

Prior to the actual production of the prefabricated bathroom, the preparatory phase is important, including planning, selection of materials, cooperation with the investor and the construction designer. Our project manager is at your disposal from the beginning of the cooperation until the approval of your project.

Floor as well as the necessary parts of the walls (shower enclosure) are coated with a water-impermeable insulating material, which prevents unwanted damage. Wall cladding and tiles are laid in a bed of flexible glue. The choice of cladding, paving and grout is made by the investor. Corners and joints are jointed with elastic sealant.

The ceiling and unlined walls are sanded, wallpapered with paint frieze and painted with dispersion paint. The external walls, visible after installation, allow the coating to apply paints and wallpapers. Sanitary and other bathroom fittings are mounted on the pod walls and connected to the individual wiring of the installation.

Each completely finished prefabricated bathroom is locked and packed during transport, thus protecting it from unwanted environmental influences. Delivery of prefabricated bathrooms by trucks is planned just in team in cooperation with the construction management. The installation process is as simple as the delivery of a prefabricated bathroom for construction, by crane directly from the truck to a specific floor and installation site. We are able to install the bathroom in approx. 30 minutes. Prefabricated bathrooms can be retrofitted by inserting through the facade, or if necessary, they can be used as a statically self-supporting tower in front of the building facade.

Wide range of use

Modular bathroom pods are suitable for all construction projects that show the use of bathrooms in larger and identical series. Monolithic concrete bathrooms offer a wide range of applications in almost all types of buildings.

Benefits of modular bathroom pods

Our project manager will take care of the complete planning, documentation, production and delivery of your bathrooms. Since we are the main supplier, we will take responsibility for all the related construction activities. In case of urgent need, faster installation can be agreed and we will speed up the implementation of your project.

We design, manufacture and equip a prefabricated bathroom based on your functional and design preferences. We adjust the size, shape and appearance to the chosen design specifications. We produce bathroom pods exclusively in various shapes and sizes to a specific object. The selection of sanitary ware, fittings, lamps and accessories is up to you.

Compared to the conventional construction, you save up to 20% of time. Construction with us represents faster commissioning and thus earlier income from the use of the building. The price is granted. The final price will be agreed upon prior to production, which protects you from price fluctuation.

Production and delivery of complete bathrooms are always aligned with the progress of your construction. Each bathroom pod is installed exactly on time. We deliver the final product to a client within 10 weeks, from planning through production to delivery to the construction site.

Modular bathroom pods are made of compacted concrete of the quality class C 25/30 (2300 kg / m3), resp. LC 25/28 (1900 kg / m3) with monolithic construction. It is the prefabrication in the hall that provides the optimal conditions for constant quality control. We guarantee qualitatively valuable results in terms of aesthetics and functionality.